Table of Contents

Juliet Towers

Contents

- Description

- Dimensions

- Assembly/Disassembly Instructions

- Storage

- Safety

- Builders' Notes

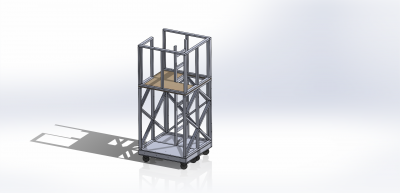

Description

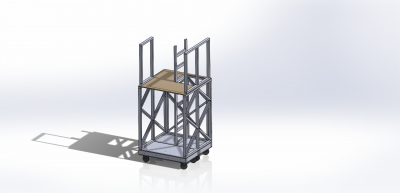

Two towers were built. The bases are 4' by 4' wide. The towers have two floors, with a central ladder to climb between them. The ground floor is at 1' high, and the top floor is at 6' high. Three sides of the ground floor are enclosed by a truss-like structure. The top handrail is continuous apart from one side, which has a half length handrail to allow walking from one tower to another (or onto a piece of 6' deck).

The towers were built as a left and right symmetrical pair. They are assembled from flat-pack parts and two weighted base pieces on wheels per tower, which are all bolted together tightly. All parts were designed to be interchangeable, allowing for almost any configuration, but due to various inaccuracies of planning and construction the parts don't all line up. A suggested design for assembling follows - deviate from this at your own risk!

The flat-pack parts are assembled with Torx head screws. Do not undo any Torx head screw during assembly/disassembly as you will be destroying the flat-pack part!

Dimensions

Assembly/Disassembly Instructions

This set of instructions is for one tower. Be sure to check you have the pieces for the right tower, otherwise the holes may not line up (sorry!).

Bolts for the bases (12mm diameter) are stored in the bases, keeping the top piece of plywood on. Bolts for the rest (10mm diameter, various lengths) are stored in two plastic chocolate boxes.

To disassemble, follow the instructions in reverse.

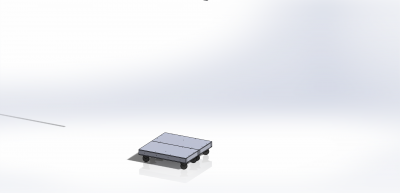

1. Bases

Begin by getting out the two 2'x4' wheeled base pieces for the tower. Undo all the bolts, and lift off the top piece of plywood from each. Put the two red-painted sides together and insert 4 long bolts through the bolt holes. Ensure all 4 sandbags (or appropriate weights) are in place and in good condition.

Replace the top plywood but do not bolt it down yet. Apply all four brakes.

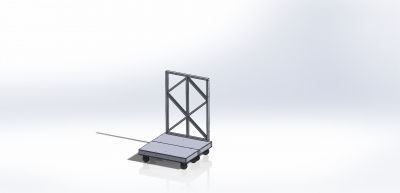

2. Back and Sides

The outer bolts on the bottom of the back and side pieces are difficult to access. You should attempt to get at least three out of four bolts installed.

Put the back piece on along the long side of one 2'x4' base piece, bolting it through the whole base piece and tightening securely (remember to use washers). Put the bolts in from the top, and reach underneath the bases to put the nuts on.

Then put the two side pieces on, along the sides which span two 2'x4' base pieces. Bolt these down securely.

Bolt each of the side pieces to the back piece, leaving the bolts sticking inwards.

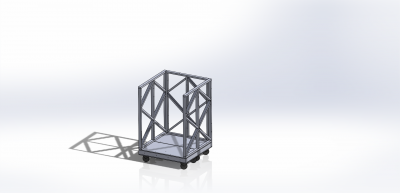

3. Top Floor

Hard hats recommended from this stage onwards.

Carefully lift the top floor onto the tower. Take care to put this the right way around. One top floor has the edge corner of the ladder cutout as a separate L-shaped piece due to a miscommunication during manufacturing. Put this in place as well. For now, it would be a good idea to place the bolts through the holes into the back and side pieces to prevent the top floor falling off.

4. Ladder

Insert the ladder from the bottom through the gap in the top floor. Bolt down through the bottom rung, into and through the base piece, and reach underneath to do these up. Bolt the ladder to the back piece with all four bolts as well.

Screw a metal L bracket into the ladder on the inside side, to brace it against the underneath of the top floor. The image below is of the L bracket on top of the top floor, but it is much easier to put it on underneath.

5. Handrails

Check the ladder and top floor are secure, and then carefully climb up to the top floor. Remember you are working at height! Have the handrails passed up and hold them in place while they are bolted in position. Put the bolts from the front handrail in from below, and put the nuts on top, so there is no protruding bolt to hit anyone's head below.

Bolt the handrails together. You may need to bend the handrails into position to insert the bolts as a couple of the pieces of wood are warped.

Storage

The 2'x4' wheeled base pieces are currently stored in Big Store and are used as wheely trollies. You can stack one on top of another if you apply both brakes on the top one!

The flat pack parts are kept in lift store. Take care when lifting these into/out of lift store as falling parts could be very dangerous. Hard hats and good communication are essential. Ensure the parts are securely tied to strong points (e.g. the heating pipe wall clamps, not the pipes themselves) before leaving unattended, so they cannot fall out of lift store.

Safety

It is essential to check the structural integrity of the towers as part of any set inspection. Repair and replace any broken or damaged parts. Be sure that the towers are safe to be used before climbing on them!

Cast should be familiarised with the towers and given the opportunity to climb them - some cast may be apprehensive!

Do not move the towers with cast on them. At least three brakes should be applied on each tower before it is climbed. It is recommended to use lighting hook-clamps mounted to a side piece to clamp the tower to an appropriately braced piece of deck for added stability. Do not assemble the towers without the sandbags in the bottom - recommended mass at least 50kg per tower.

Be aware of the open handrail and do not position the tower so the open handrail leads to a drop! Ensure the edges of the top floor are clearly marked in white tape, and familiarise the cast with the hazards of using the towers in a dark environment.

The top handrails are not designed to be load-bearing.

Decorative materials can be applied to the outside of the tower, but should use the minimum number of small screws so the structural wood is not compromised. Limit the weight of any decoration attached to the top half of the tower.

Builders' Notes

The towers were built in January 2023, to be first used in The Addams Family. They were designed by Jonathan Ferguson and built by him and a team of dedicated crew over the period of two full days and one evening. The total cost was significant (>£300), which was paid for by StageSoc as the towers will be an asset used for many shows to come (hopefully!).

The SOLIDWORKS CAD model and all the PDF part drawings are here: download Towers V3.zip

The materials used were: 63x38mm CLS studwork from Wickes 1220x2440mm 18mm structural plywood from Wickes* 47x100mm carcassing timber from Jewson (for the base structures) Torx screws throughout (to stop anyone accidentally over-dismantling the flat pack pieces during get-outs! M12 bolts (for the base piece bolts) M10 bolts of varying lengths elsewhere

The aim was to build the flat pack parts to be interchangeable. Due to some oversights in the design (i.e. Wickes CLS is 2400mm long, not 2440mm) not all of the bolt holes lined up. Many were fixed by judicious application of a larger spade drill bit, however this means there may be inconsistencies between parts. Because of this, it was decided to allocate each part in its specific place to aid easy reassembly.

The towers were designed to be neutral, so that they can be decorated appropriately for the show in question. This could include solid walls (3mm plywood is recommended) on any of the four sides (remember to leave an exit route!).

Having said this, it is theoretically still possible to re-configure the towers. For instance, it should be possible to configure either tower as a “left” or “right” tower, by flipping the top floor panel over (the ladder is in the centre so does not need to move). Equally, the handrails on the top floor could be re-adjusted (however new bolt holes to join the handrails to each other may be needed as the placement of these was not measured!).

In theory, both towers could be bolted together to make a 4'x8' mega tower. This would be very cool.

The base plates can be assembled in any configuration to make a piece of 1' tall wheely deck. Bolt holes along the sides should all match up to enable this. The top handrails should in theory be able to attach to the baseplates as well (although this is much less certain).

Using the drawings and by measuring the towers themselves, it would be possible to build extra pieces, such as stronger or different length top handrails, shorter/taller sides etc.

The Wickes Trip

Jonathan's estate car was not large enough to fit the large pieces of uncut ply. To get them from Wickes to the Annex, he took 4 unwitting volunteers (Cerys, Ellie, Simon and Sy) and the wheely board in his car to Wickes, tied the ply vertically to the wheely board, and left them to make their way back by foot. This was unadvisable and should not be repeated. The aforementioned volunteers should be commended for their tireless work to bring the 3 pieces of plywood back to the Annex.